Sustainable case coding

1-litre of UBS ink can print the equivalent

of 350Kg of labels and costs 6-8 times less

UBS Aplink High-Resolution Inkjet Printers

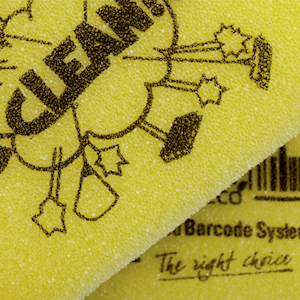

The United Barcode Systems Aplink high-resolution inkjet printer range includes models to print text, detailed graphics, barcodes and 2D codes onto porous and non-porous surfaces. For printing onto porous surfaces including cardboard, paper and timber, mineral-free oil-based ink is used and for non-porous surfaces, polymer-based inks are used and immediately cured using the latest UVLED technology.

For applications requiring a single printhead, the Aplink LCX series offers a cost-effective solution with a 72mm printhead, ink system and touch screen controller built into one unit. Where more than one printhead is needed, the Aplink MRX72e series enables up to four printheads to be driven from a single controller. For all systems, printheads are available to print onto the side or top of products and the MRX72e models also have the option of umbilical printheads to fit into confined and remote positions.

Whether printing onto porous or non-porous surfaces, using UBS Aplink printers as an alternative to applying labels offers significant cost savings and environmental benefits. Typically a single one-litre bottle of UBS ink replaces 350Kg of labels and costs 6-8 times less than the equivalent labels and printing ribbons. The environmental benefits include significant haulage carbon savings by shipping just 1Kg of ink for each 350Kg of labels and avoiding the need to dispose of 140Kg of backing paper waste for each litre of ink used which cannot be recycled with other paper waste.

UBS Aplink systems come with UBS Designer PC-based software to design and upload virtually unlimited numbers of print images into the printer memory. It is also possible to connect to host systems to automatically select print images and populate variable data fields without operator intervention.

UBS Aplink Series

Aplink LCX

Self-contained high-defintion inkjet printer with 72mm print height. Print text, detailed graphics, barcodes and 2D codes onto porous and non-porous materials.

Download brochure

Aplink MRX72e

Modular high-defintion inkjet printer series with up to 4 x 72mm high printheads per controller. Print text, detailed graphics, barcodes and 2D codes onto porous and non-porous materials.

Download brochure

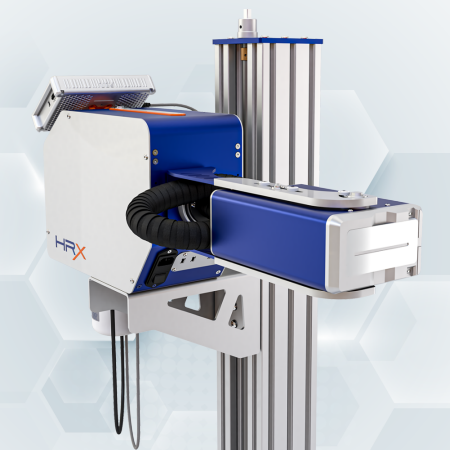

Aplink HRX

Advanced high-resolution printer series with resolution up to 360 x 1440 dpi and up to 7 greyscale levels. Up to 4 printheads can be driven by a single controller to print onto porous and non-porous materials.

Download brochure

Sustainable carton coding

Printing directly onto cartons and packs offers significant environmental benefits as well as reducing costs by typically between 6 and 8 times compared to applying labels.

Find out more