UBS Aplink LCX UV LED

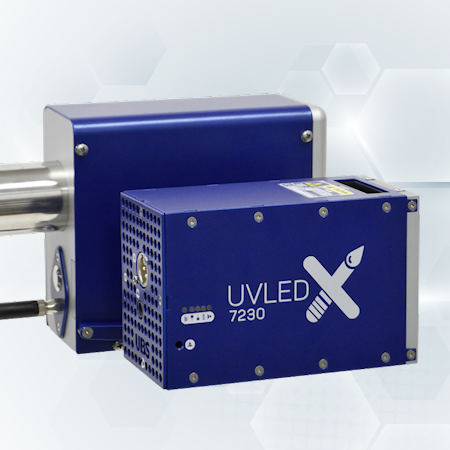

Self-contained high-resolution inkjet printer for printing onto non-porous surfaces including plastics and metals. The Aplink LCX UV LED is ideally suited to applications where a single 72mm high printhead is required. The printhead, ink system and 5.7" touch screen controller are housed in a single, compact unit.

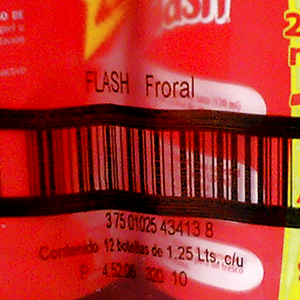

Text, detailed graphics, barcodes and 2D codes can be printed at 180dpi vertical resolution x up to 360dpi horizontal resolution using polymer-based UV-curing ink that dries instantly using the latest UV LED technology. The high-capacity 1-litre ink bottle can be changed on the fly without interrupting production.

Using the Aplink LCX UV LED as an alternative to applying labels offers significant cost savings and environmental benefits. Typically a single one-litre bottle of UBS ink replaces 350Kg of labels and costs 4-5 times less than the equivalent labels and printing ribbons. The environmental benefits include significant haulage carbon savings by shipping just 1Kg of ink for each 350Kg of labels and avoiding the need to dispose of 145Kg of backing paper waste for each litre of ink used which is virtually impossible to have recycled.

UBS Aplink systems come with UBS Designer PC-based software to design and upload virtually unlimited numbers of print images into the printer memory. Printers can then run in stand-alone mode without a PC connected using the touch screen controller to select the required print image and enter variable data such as batch code and expiry date. It is also possible to connect to host systems to automatically select print images and populate variable data fields without operator intervention. Martek offers integration services to connect printers to a wide range of host systems.

Specification |

| Printhead: | 72mm Seiko 4th generation piezo-electric printhead |

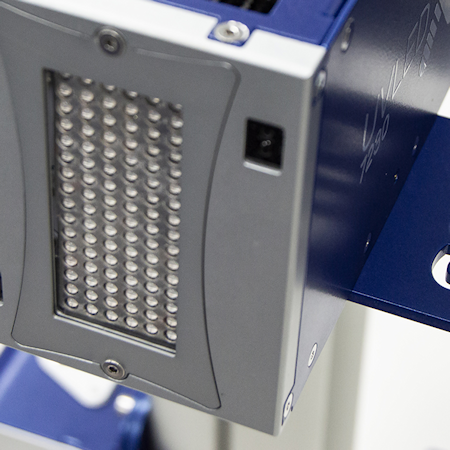

| Ink curing: | UV LED technology 72x30mm or 17x30mm array |

| UV system durability: | At least 20,000 hours |

| Print direction: | Forwards onto product side or down onto top of product |

| Ink type: | Low migration polymer-based UV-curing ink in 1-litre containers |

| Ink colour: | Black - others on request |

| Print resolution: | 180dpi vertical x up to 360dpi horizontal |

| Text printing: | Any font in any point size and rotation including date, time, offset date, counters and external inputs |

| Graphics printing: | Detailed graphics up to 72mm high |

| Barcode printing: | All common barcode formats supported including UCC/EAN-128 |

| 2D code printing: | QR and Datamatrix codes |

| Print frequency: | Up to 2 prints per second |

| Print speed: | Up to 50m/min |

| Printhead to product distance: | Up to 5mm for optimum print results |

| Controller: | Built-in 5.7" colour touch screen (640 x 480px) |

| Standard interfaces: | USB2.0, Ethernet LAN |

| Optional interfaces: | RS232 serial |

| Software: | UBS Designer included as standard - UBS Designer Pro and Codesoft optional |

| Options: | Shaft encoder, cold environment kit, status beacon, RS232 serial interface, stand, barcode validation, integration services |

| Power supply: | 110-240Vac @ 50-60Hz |

| Download BrochureUBS Designer Software Brochure |

Features and Options

UV LED Curing

Instant drying on plastic and metal

UBS Designer Software

User-friendly print editor

Barcode Readers

Inline barcode quality management

Integration Services

Automatic printing configuration

UV LED Curing

Low-migration, polymer-based ink is used by the LCX UV LED and cured instantly using the latest UV LED technology.

Text, barcodes and detailed graphics can be printed onto non-porous materials including metals, plastics, glass, poly-woven bags, EPS and synthetic textiles.

For production lines where a combination of porous and non-porous packaging is used, the LCX UV LED makes an ideal soultion.

Direct printing offers considerable cost and environmental bebefits compared to applying labels. Typically, costs are 4 to 5 times lower and there is no backing paper waste to dispose of which is extremely difficult to have recycled.